Explosion Proof 5t ELK Single Girder Cranes

| Project Ref: | 60213 |

| Client: | JKC JV |

| Project: | Ichthys Project Darwin NT Australia - the World's biggest LNG project |

| Scope: | Design, Manufacture & Supply 5 off 10t x5m EDL Underslung Cranes 2 off 30t x 8m ZLK Double Girder 2 off 15t x 8m ZLK Double Girder 8 off 63t x 19m ZLK Double Girder 2 off 90t x 15m ZLK Double Girder All Zone 2 IEC EX explosion proof Cranes |

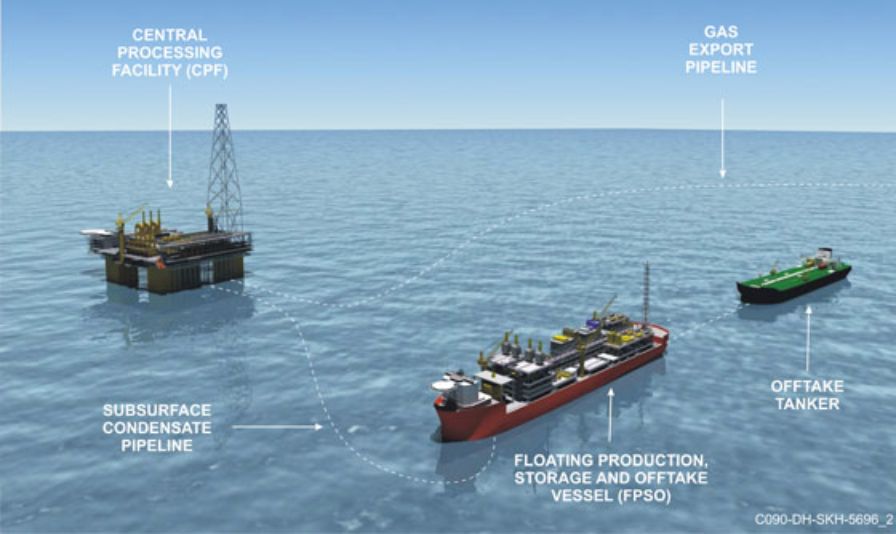

Gas from the Ichthys Field will undergo preliminary processing at the offshore central processing facility (CPF) to remove water and raw liquids, including a large proportion of the condensate. This condensate will be pumped to a floating production, storage and offloading (FPSO) facility anchored nearby, from which it will be transferred to tankers for delivery to markets.

The gas will be transported from the CPF through a subsea pipeline more than 885 kilometres to the onshore LNG processing plant proposed for Blaydin Point on Middle Arm Peninsula, Darwin, Northern Territory. It will be cooled to below minus 161 degrees Celsius, the point at which the gas becomes a liquid, known as liquefied natural gas.

The Ichthys Project will have an initial capacity to produce 8.4 million tonnes of LNG per annum and 1.6 million tonnes of liquefied petroleum gas (LPG) per annum, as well as approximately 100,000 barrels of condensate per day at peak.

The Project is now in the construction phase, following a Final Investment Decision (FID) in January 2012. Mobilisation for construction of the Project has begun, with preliminary works to commence shortly.

Onshore Facilities

Onshore facilities will include:

- Two LNG trains with a capacity of 8.4 million tonnes per annum

- LPG and condensate processing plants

- Storage tanks for LNG, LPG and condensate

- Administration facilities

- Utilities and services

Offshore Facilities

Key offshore facilities will include:

- Semi-submersible Central Processing Facility (CPF)

- Floating Production Storage and Offloading (FPSO) unit for condensate treatment and storage

- Umbilicals, risers and flow lines (URF)

- 885km export pipeline to Darwin

Challenge

Eilbeck Cranes has won a new order for the supply of crane for the Ichthy’s Project through an demanding tender process which lasted 6 months. It was through the commitment of Eilbeck Cranes staff which allowed us to be flexible and supply technical design support for the preliminary upfront design allowing the client to continue with the plant design during the tender phase. The project would be one off, if the not the largest single crane contract to be let in Australia over the past 40 years and there is still additional crane on hold and under review still to order increasing what I already sizeable contract. The cranes are to be fully designed and manufactured by Eilbeck Cranes Perth three factories using Ex wire rope hoists and crane components meeting the Quality, Spl. Documentation and Australian Standard Certification requirement for Hazardous area Cranes at very short delivery period for these special cranes.

We at Eilbeck Cranes are committed to meet the project requirement.