LNG Tank Jib Cranes

"We draw on our Profound Experience and Knowledge in the Ex-proof Area of Expertise to Ensure a Quality Product.”

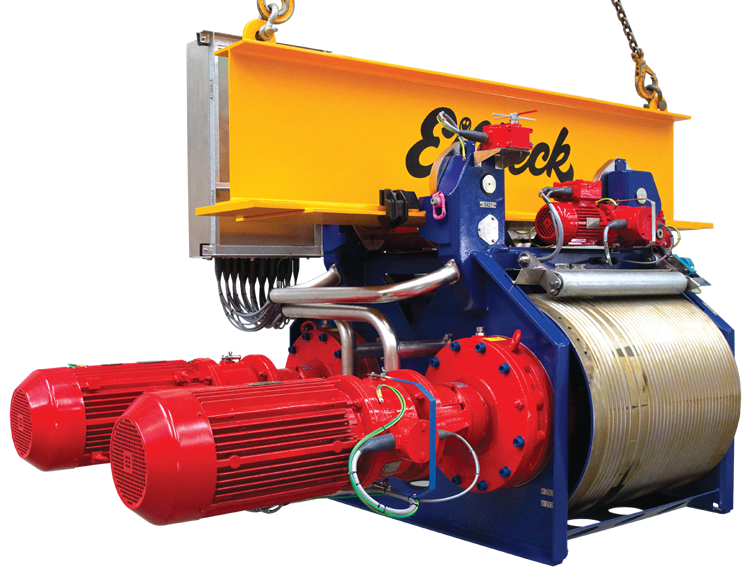

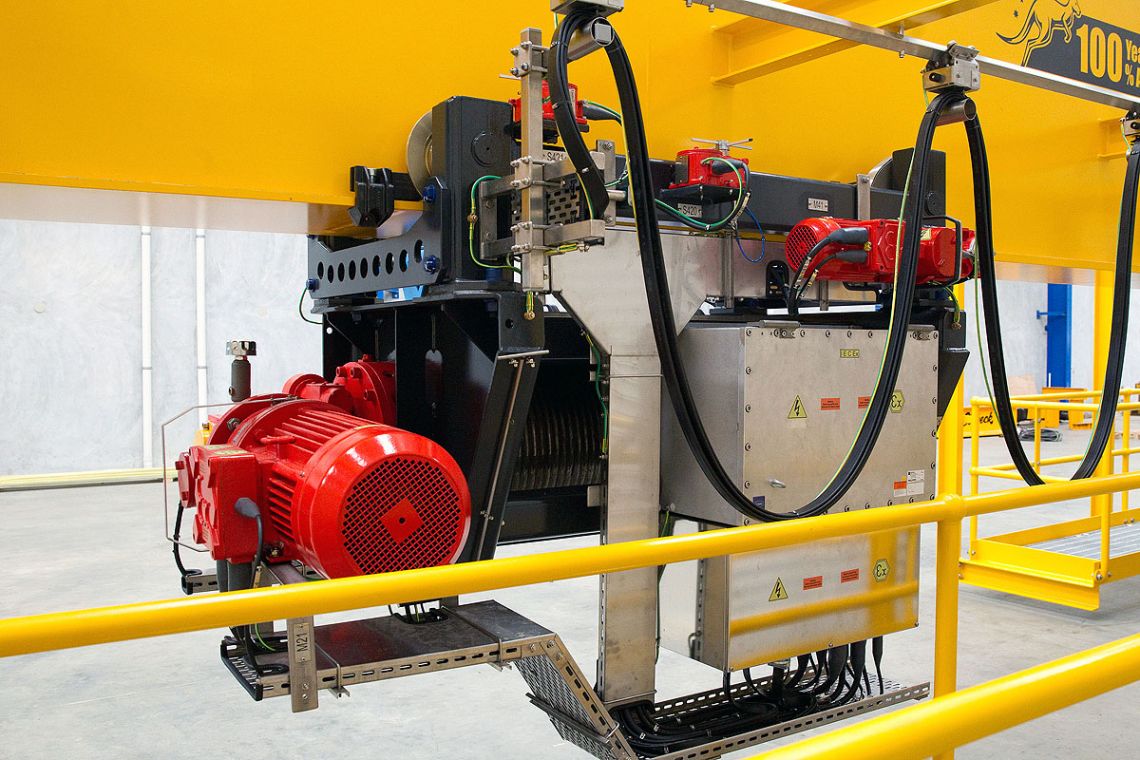

Eilbeck Cranes has embraced the embodiment of perfection in lifting and crane technology all over the world for many years. Compact, high-performing and particularly maintenance friendly Ex-proof components produced at Eilbeck's factories, have users, crane manufacturers and system manufacturers appreciate the modular system based, on field-proven, low-maintenance ex crane and hoist products. Serial manufacture of standard components means economic advantages for Eilbeck’s clients and partners. This combined with precision machining done entirely in-house at Eilbeck’s workshops results in a superior top quality product at competitive price.

Eilbeck Cranes has supplied LNG tank cranes to Entrepose for projects in Nigeria, Algeria and most recently for Chevron’s Wheatstone Project in Australia’s North West. Entrepose again sought a technical proposal from Eilbeck for the 4 LNG Tank Jib Cranes and 4 Auxiliary Jib Cranes to include a comprehensive solution to operate in such a harsh environment.

Eilbeck supplied 4 off 7.35t Pillar Jib Cranes VS and LS Type for Entrepose France and Thiess Australia to be used for the Wheatstone LNG Project at Onslow site in Western Australia.

Supplied Jib Cranes Features:

- 4 off LNG Tank Pump handling Jib Cranes

- Capacity: 7.35t @ 17.125m radius, 5.4t @ 19.125m radius & 0.9t@ 20.125m radius

- Under side of jib arm to base of the jib crane: 11.86m & lifting height 71m

- Zone 2 Ex de IIB T3 IECEx

- Fully designed to project specification

- Full maintenance access ladder and platform

- Non sparking features as solid bronze wheels and bronze coated hooks

- Lightening protection

- Motors and gear box of cast iron body suitable for corrosive environments

- Non-sparking diamond track SS catenary system for power supply system

- Manual lowering in case of power failure

- Designed for cyclonic area complete with manual storm lock

Yamal is one of the most complex liquefied natural gas (LNG) projects ever undertaken because of its location above the Arctic Circle, a region that is icebound for 7 to 9 months of the year.

Following the project launch at the end of 2013, plant operator Novatek along with project partners, CNPC, Total and Silk Road Fund, awarded the contract for the construction and commissioning of the 4 LNG storage tanks to Tuyauteries Maintenance & Services Industieriels (TSMI) acting on behalf of Entrepose Projects and Vinci Construction Grands.